INDUSTRIAS GM & SINCALOR

Colombia, Venezuela, Ecuador, Perú México, Panamá, Argentina, Chile, Costa Rica, Guatemala, Uruguay, España, Usa.

Si buscas

hosting web,

dominios web,

correos empresariales o

crear páginas web gratis,

ingresa a

PaginaMX

Por otro lado, si buscas crear códigos qr online ingresa al Creador de Códigos QR más potente que existe

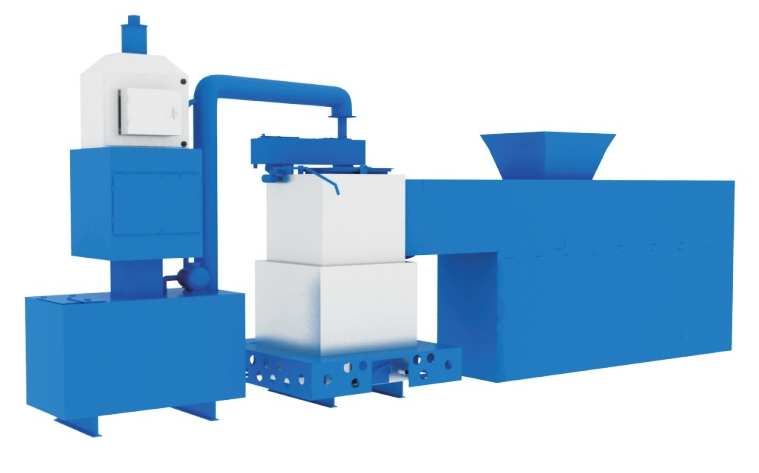

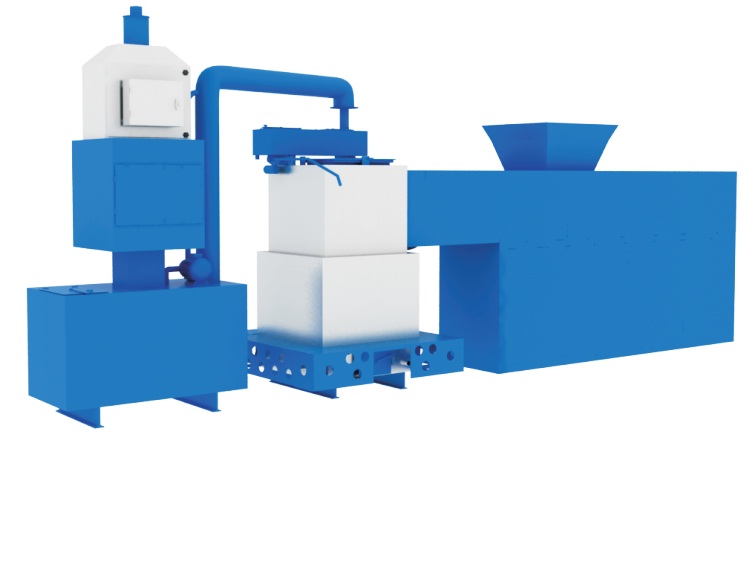

HORNO INCINERADOR DE DESECHOS SIN CONSUMO DE ENERGIA

Performance characteristics:

1. Energy saving: Operation is without a need for oil, electricity or any other fuel.

Only the conveying system and the gas operation system use a few of electricity.

2. Harmlessness: The disposal of residue and emission of exhaust gas after processing are in line with national standards.

3. Obvious reduction: After the treatment, residue accounts for 3-5%.

4. Small occupation: Able to process near the garbage source without transshipment and centralized treatment, saving land resources.

5. Easy operation: The common sanitation worker can operation through short-term training, and the machine is easy in operation and maintenance.

Thanks for interesting of our garbage processor. The equipment is design for solve the garbage problem that trouble almost every government. At the moment, government has to pay a lot every day to collect and transport the garbage to some place far away from city to bury or burn, and even so, it still lead to a serious pollution problem.

We develop the equipment as a small process station which could be placed nearby town or living area to process the garbage, in this way, it could save a lot of transport and process fee. And most important is that it cost almost nothing to decompose garbage into ash, so it means we could solve the garbage problem in a very low cost by this new technology.

The emission of equipment are very clear, the laboratory certification from the most powerful lab show that the pollution index of our equipment are very low, which far lower than the standard of USA and EC.

For a small town of 2,000 of population, normally the garbage output is about 2000kg/day(1.0kg/day.person), it only needs a small equipment (model GM1500), and a small area about 100m2 for the station, after that, no need of any other energy source for process the garbage, only a small electric power for process the smoke, which about 80kw.h/day. In this way, we have built a lot of station for town and village to solve their garbage problem in a very low cost, and we have 2T/day, 4T/day and

8T/day3 models of capacity.

HOSPITALES:

Desechos Médicos Hospitalarios.

EDIFICIOS INDUSTRIALES:

Fábricas, Almacenes.

HOTELES:

Primera Clase, Clase Media, Moteles.

ESCUELAS:

Primarias, Secundarias y Universidades.

RESIDENCIAS:

Casas Privadas y Edificios de Apartamentos.

INSTITUCIONES:

Asilos, Residencias para Ancianos.

EDIFICIOS COMERCIALES:

Centros Comerciales, Supermercados, Restaurantes.

Servicio de Certificación Universal

Sistema de Certificación para Control de Calidad

Máquina Térmica Procesadora de Basura

El Sistema de Control de Calidad es conforme a la siguiente norma:

GB/T19001-2000 — ISO9001:2000

Cobertura del Sistema de Control de Calidad:

Diseño y Producción de Tubos Rectificadores Generales, SCRs Generales, Módulos Relevantes y Máquina Térmica Procesadora de Basura *.

Fecha de Expedición: Marzo 29, 2007

El horno importado por cualquier persona jurídica, se paga con el impuesto de renta, de acuerdo a los siguientes decretos:

Los hornos estan exentos del impuesto a las ventas.

Resolucion 0978 04 Junio 2.007

Protocolo de Kyoto

Covenio de Viena (PDF)

-Ahorra Energía. Opera Sin Ningún Tipo de Energía Eléctrica o Combustible.

-No Genera Olores Desagradables.

-No Impacta el Medio Ambiente.

-Diseño Práctico, No Ocupa Mucho Espacio.

-Fácil de Operar.

-Todo Tipo de Residuos Pueden Ser Tratados.

-Las Cenizas Extraídas se Pueden Utilizar Como Abono Orgánico.

-Diseño Práctico, No Ocupa Mucho Espacio.

-Fácil de Operar.

-Todo Tipo de Residuos Pueden Ser Tratados.

-Las Cenizas Extraídas se Pueden Utilizar Como Abono Orgánico.

Horno Incinerador de Desechos

-The machine can process many things except stones, glass, iron and something like that.

-Each machine model can fully process the garbage in about 4 hours in the condition of 40% ambient humidity. Of course the machine can work 24 hours all the day.

-The working principle of the machine is not burning. There is no fire in the machine; we are making use of the energy of the hydronium to heat the garbage then make it decompounds. After processed, the ash in the bottom of the machine which you can get is a fertilizer for the field. It can be sold to a farmer.

-It is necessary to put the machine under some canopy or cover to protect the machine from drenched by the rain.

-The Gas Processor (the pipe) will last shorter than the garbage machine.

-THE MACHINE CAN RELEASE ABOUT 5 KG OF ASH WHEN IT FINISHES PROCESSING 1 TON OF DAILY GARBAGE. IT ALSO DEPENDS ON THE KING OF GARBAGE.

-Basically, you don't need to do any installation for the GARBAGE PROCESSOR but the EXHAUST GAS PROCESSOR.

- Anything you put into the machine that cannot be processed would be release with the ash together at last. These things would never damage the machine.

-The machine can process solid type of waste but not liquid waste.

-All kind of batteries are ok except liquid batteries.

-Fibra de vidrio, asbestos, sales estabilizadas, vermiculita fina, vermiculita media, enviroblend no pueden ser procesados.

-Afirmativamente la horno procesa mercurio, el humo es toxico para la atmosfera. Si se desea procesar elementos tóxicos como desechos químicos, médicos e industriales, es necesario utilizar EL EXOSTO DE PROCESAMIENTO DE GAS con la maquina todo junto, usado para procesar el humo toxico. Después de procesado, el humo hacia la atmosfera es limpio y seguro. Para basura diaria domestica no es necesario este EXOSTO el cual consume solo un poco de electricidad. Los archivos de prueba se realizaron por compañías autorizadas por el gobierno, significa que es algo confiable. Respecto a las cenizas, ya se han usado en terrenos con resultados satisfactorios.

-The machine is not totally hermetic. When the machine is working, you can open the feeding door any time you want then you can add the garbage. And we suggest you that you’d better keep adding garbage into the machine and keep the machine working all the time (24 hours every day) if you have enough garbage and waste. Because the machine needn’t any stop.

-You won’t feel too hot when you are close to the machine because the temperature of the surface of the machine is just about 35 to 50 centigrade. So you won’t feel hot even if you put the machine in a house.

-You can open the feeding door directly to see the procedure of the machine. You’d better to keep putting the waste into the machine all the time and do not let the machine stop or the container empty.

-The heat-resistant materials inside the machine needn’t any maintenance.

-The working manpower labour depends on your requirement. As usual, you just need to arrange one or two people to operate the machine and add the garbage.

-All the operation of the machine can be done only by one person and all the valves can be manual switched. The feeding door also can be opened by the worker. There is also available a new automatic equipment for the garbage feeding. If you use the device with the machine together, the speed of the garbage feeding will be faster. And the residues generated in processing can be exhausted both through the front dust exhaust door 8 and the rear dust exhaust door 9.

-It has one year warranty.

-If you use this machine to process the medical or hospital garbage, the ash collected from the machine may contain some element not suitable for the field.

-Processed water steam is exhausted through the steam outlet 2. The carbonized valve 1 can be connected with a normal plastic pipe or metal pipe because the temperature of the released steam is very low. But the normal plastic pipe or metal pipe is not the same as the EXHAUST GAS PROCESSOR. If the garbage contains some chemical element or some poison thing, you'd better use the EXHAUST GAS PROCESSOR.

-There is not any maintenance for the whole set of machines and the EXHAUST GAS PROCESSOR. The machine must be just protected from rain.

-THE EXHAUST GAS PROCESSOR reaches 1100 °C, and the temperature inside the center of the machine is about 700°C. But you won’t feel this high temperature because we have 3 levels filter on the center of the machine.

-The machine can process with the feeding door or lid opened but it is not recommended to open it for too long because it will always release some smoke from the door although the smoke is safe for our body.

-If you put garbage into the machine, you don’t have to make it compacted like a cube.

-We use newspaper to strike the fire. This is necessary for you to use the machine at the first time. The machine needs the heat of the fire to power on and start working. So you have to burn something to start the machine. Of course you can burn not only the newspaper but also any paper or some woods and anything can be burned. But I think if you burn the newspaper is a very cheap method and very convenience. And the position for you to strike the fire is the ash box. So you can see paper is burned and throw it into the ash box. After this procedure, the machine starts working.

-There is not an exactly time to make the temperature reach 700"C, because the process procedure does not depend on the temperature. Even you start the machine it can process the garbage at once. But it will need almost one day to make it stable.

-The two valves shown on the video are used to choose the way you release the exhaust gas. If you switch on the left valve and switch off the right valve, the second burner will be turn off and the exhaust gas will be released directly from the vertical pipe without processed. If you switch off the left valve and switch on the right valve, exhaust will be released from the second burner (the right side pipe), and the gas will be processed before this is released to the air. It is suggested that you should use the second burner if the garbage contain many plastic or rubber (chemical waste).

-The machine can process perfectly all kind of plants and herbs.

-The machine can be turned off any time if you do not need it. Also you can use it all the time and never stop. But if you do not have enough garbage to process, the machine will turn off by itself. If you want to keep it working, you should keep adding the garbage.

Objetos que puede procesar:

- Plásticos.

- Periódicos, Revistas, Libros.

- Objetos de Algodón.

- Residuos de Construcción y Residuos Plásticos Agrícolas.

- Basura Diaria.

- Residuos Industriales y Objetos de Goma o Caucho.

- Residuos Médicos Hospitalarios.

.jpg)

Objetos que no puede procesar:

- Metal (Latas, Aluminio Duro etc.).

- Vidrios, Cerámicas

- Yeso, Cemento

- Líquido

CLIC AQUÍ PARA BAJAR LOS DOCUMENTOS IMPORTANTES PARA COMPLEMENTAR LA INFORMACIÓN SOBRE LOS HORNOS INCINERADORES

Copyright © 2013 INDUSTRIAS GM Inc. All rights reserved.

Tu Sitio Web Gratis

© 2025 INDUSTRIAS GM & SINCALOR40107